Multimaterial 3D Printing: A Technological Leap Forward

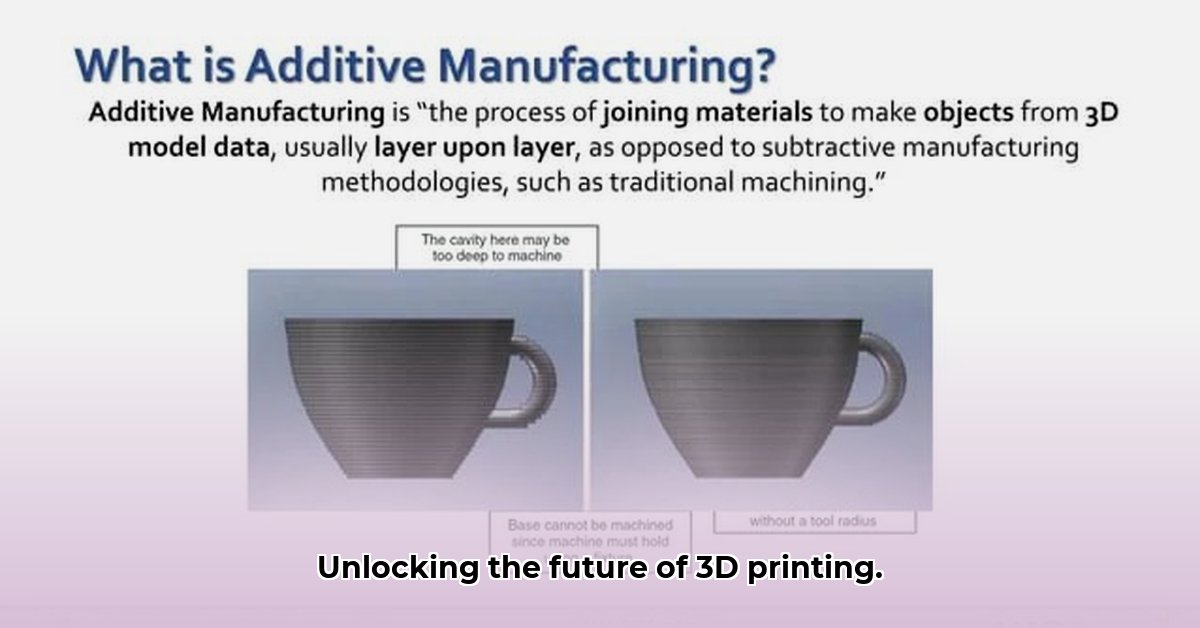

Imagine constructing objects layer by layer, not with a single material, but with a strategic blend of multiple materials—combining strength, flexibility, and other properties within a single structure. This is the promise of multimaterial 3D printing, a rapidly evolving technology transforming design and manufacturing. However, realizing this potential presents significant challenges, necessitating innovative solutions and a deep understanding of material interactions and process control. Christopher Spadaccini’s research plays a pivotal role in addressing these complexities.

The Complexities of Multimaterial 3D Printing

The potential benefits are vast. Consider personalized medical implants perfectly matched to a patient's anatomy, or lightweight yet incredibly strong automotive parts designed for optimal performance. However, the reality is far more complex. Different materials often exhibit poor interfacial adhesion (i.e., they don't bond well). This leads to weak points compromising the integrity of the final product. Maintaining consistent material properties across all scales—from microscopic bonding to the macroscopic object—is crucial for reliability. This requires rigorous control over the printing process and careful material selection.

Christopher Spadaccini's Contributions

Dr. Spadaccini's research tackles these challenges head-on. His work focuses on the detailed interactions between materials during 3D printing, providing practical solutions for optimizing the process and improving final product quality. His findings are not just theoretical; they offer tangible strategies for engineers and manufacturers facing real-world problems. His publications are often accessible through academic databases such as [insert relevant database link examples here].

Key Challenges and Solutions

The path to realizing the full potential of multimaterial 3D printing requires a multifaceted approach:

Material Science Advancements: Developing new materials with enhanced compatibility and predictable properties is paramount. This includes materials designed to bond seamlessly during the printing process.

Enhanced Printing Precision: Current 3D printing techniques—extrusion, inkjet, binder jetting, etc.—require significant refinement to achieve greater precision and control over material deposition and layer adhesion.

Automation and Scalability: Automation is essential for industrial-scale production. This includes developing robust robotics and sophisticated software capable of managing the complexities of multimaterial printing efficiently and consistently.

Establishing Industry Standards: Widely accepted standards for materials, processes, and testing procedures are necessary to ensure product reliability and build confidence in the technology.

The Impact of Spadaccini's Research

Dr. Spadaccini's research offers invaluable insights for engineers and researchers. His work often includes detailed analyses of material behavior, strategies for process optimization, and the exploration of novel printing techniques. This blend of theoretical understanding and practical application is critical for driving innovation in the field. His findings significantly contribute to the overall progress of multimaterial 3D printing.

Future Applications Across Industries

Multimaterial 3D printing promises to revolutionize various sectors:

- Aerospace: Manufacturing lighter, stronger, and more fuel-efficient aircraft components.

- Automotive: Creating highly customized, strong, and lightweight car parts.

- Healthcare: Producing personalized prosthetics and implants.

The potential applications are vast and continue to expand as the technology matures.

Addressing Scalability Challenges in Large-Scale 3D Printing

Large-scale 3D printing (LS3DP) presents unique scalability challenges, including material compatibility issues, precise process control across vast scales, and the economic implications of scaling up manufacturing infrastructure. These challenges highlight the need for:

Robust Material Compatibility Testing: Rigorous testing is vital to ensure seamless integration of diverse materials.

Advanced Process Control Systems: Real-time monitoring and feedback loops are crucial for maintaining print accuracy and consistency during large-scale production.

Refined Scalable Printing Technologies: Improving existing technologies and developing new ones that are specifically designed for large-scale operations is critical.

Industry Collaboration: Collaboration among researchers, manufacturers, and end-users is crucial for facilitating innovation and addressing shared challenges.

Standardized Industry Guidelines: Establishing clear benchmarks for material performance, print quality, and safety will enhance confidence and reliability.

By strategically addressing these challenges, we can unlock the transformative potential of multimaterial 3D printing, shaping the future of manufacturing and various industries. The ongoing research, including Dr. Spadaccini's contributions, is paving the way for significant advancements in this field.

⭐⭐⭐⭐☆ (4.8)

Download via Link 1

Download via Link 2

Last updated: Saturday, April 26, 2025